Leave Your Message

High Current Transformers (HCT) play a vital role in modern industrial applications. These devices are designed to handle significant electrical currents while ensuring safety and efficiency. Industries, ranging from manufacturing to energy production, rely on HCTs for effective power management.

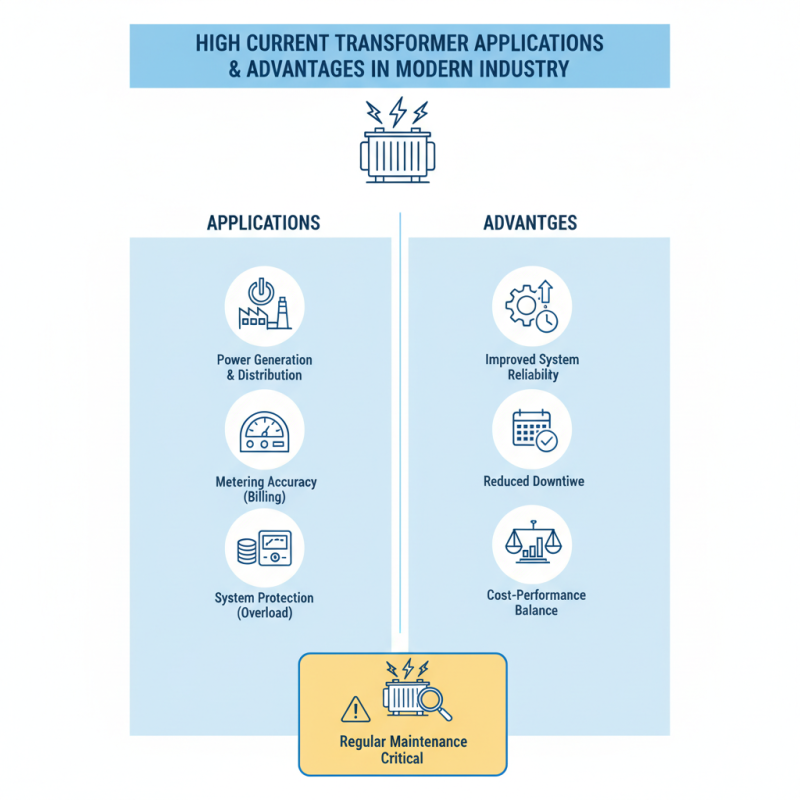

In power generation, HCTs help step down high voltages. This makes electricity safer for distribution. Their precision is critical in monitoring and controlling systems. HCTs also enhance metering accuracy, which is crucial for billing and efficiency. Moreover, they protect systems against overloads. Even in sophisticated setups, something might go wrong. It's essential to regularly check these transformers to avoid failures.

The advantages of High Current Transformers extend beyond functionality. They often improve system reliability and reduce downtime. However, maintenance costs can add up. Balancing costs and performance requires careful planning. Understanding these factors can lead to better decisions in industrial applications.

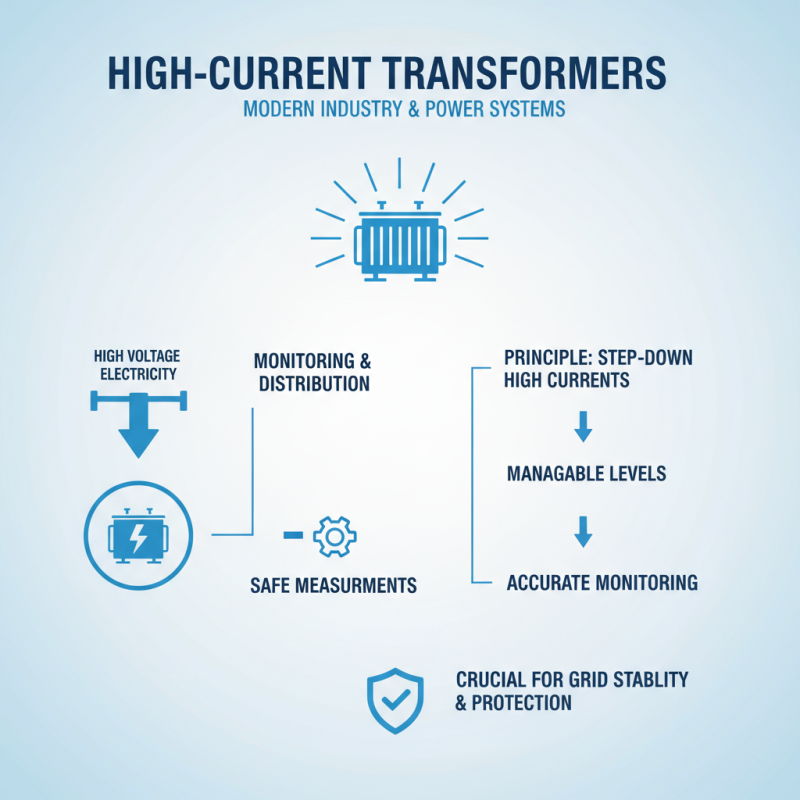

High current transformers play a crucial role in modern industry, especially in power system management. They are vital for monitoring and distributing high voltage electricity. Understanding their basic principles can help appreciate their significance. High current transformers work by stepping down high currents to manageable levels. This process allows safe measurements for monitoring purposes.

Industry reports indicate that the adoption of high current transformers is growing. According to a recent study, the market for these devices is expected to exceed $5 billion by 2025. These transformers help in reducing energy losses by maintaining high efficiency up to 98%. However, not all installations are optimal. Some facilities experience calibration issues that can lead to inaccurate measurements. Ongoing training for personnel is essential to avoid these problems.

In many cases, the installation process of high current transformers could be improved. Improper installation may cause overheating or mechanical failures. It is essential to adhere to best practices during setup. Operators must also consider environmental factors affecting performance. Reports suggest that about 20% of transformers in the field suffer from various operational challenges. Investing in technology and training can significantly mitigate these risks.

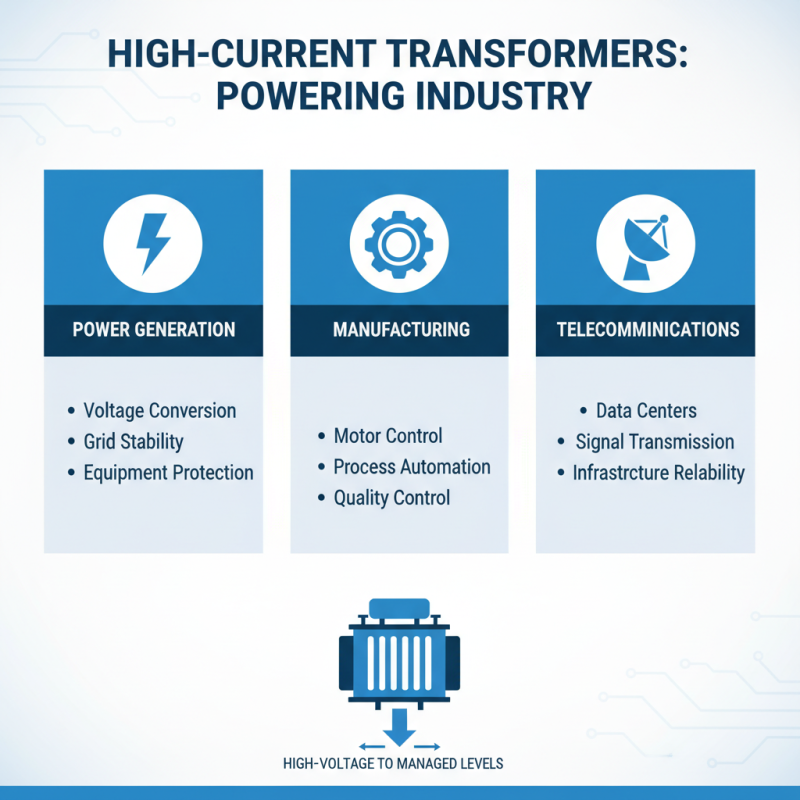

High current transformers are essential in various industries. They transform high voltage currents into manageable levels for measurement and control. This capability is vital in sectors such as power generation, manufacturing, and telecommunications.

In power generation, these transformers ensure efficient transmission. According to a report by the International Energy Agency, about 80% of electricity is transmitted using high current systems. This statistic underscores the significance of transformers in managing energy flow. In manufacturing, high current transformers are crucial for equipment like welding machines. They help maintain the stability of operations, preventing equipment damage due to overload.

Telecommunications networks also rely on high current transformers. They facilitate reliable data transmission over long distances. However, there are challenges. Transformer failures could disrupt communication, causing significant downtime. Maintenance is often overlooked, leading to unexpected failures. Industry professionals must prioritize regular inspections to prevent these issues. In today's fast-paced environment, addressing these concerns is more crucial than ever.

High current transformers (HCTs) bring numerous advantages over traditional solutions. Their primary function is to accurately measure high electric currents. Unlike conventional transformers, HCTs can handle larger currents without significant distortion. This feature is vital in industrial settings where efficiency is crucial.

One major benefit is their compact design. HCTs occupy less space on equipment panels compared to traditional transformers. This compactness leads to easier installations and reduces clutter. Their durability is another asset. They are built to withstand harsh environments, providing reliable performance over time. Reliability translates to fewer interruptions in operations, which is a constant concern in manufacturing processes.

However, high current transformers are not infallible. They can be complex and may require specialized knowledge for installation and maintenance. The initial cost can also be a barrier for some industries. Balancing these factors is essential. Despite the drawbacks, the benefits often outweigh the challenges. The advantages of HCTs contribute to more streamlined processes and enhanced productivity in modern industries.

| Application | Advantages | Traditional Solution Limitations |

|---|---|---|

| Welding Equipment | High efficiency and reliability in high-load conditions | Inability to handle high currents without overheating |

| Power Generation | Improved voltage regulation and operational stability | Lower performance under fluctuating loads |

| Renewable Energy Systems | Enhanced integration with solar and wind generation | Poor adaptability to renewable energy fluctuations |

| Industrial Automation | Faster response times and increased control precision | Slower operation and greater wear and maintenance needs |

| Metal Processing | Consistent performance with varying thicknesses | Injustice to material variations leading to quality issues |

Implementing high current transformers in modern industry presents several challenges. One major issue is ensuring accurate measurement. High currents can lead to heating and saturation, affecting performance. Engineers must conduct thorough calculations to prevent these problems. Any oversight can result in data inaccuracies.

Another challenge is the physical space these transformers require. They are often bulky and heavy. This can restrict installation options, especially in tight spaces. Additionally, maintenance is a concern. Regular checks are needed to ensure reliability. Neglect can lead to failures.

Safety is of utmost importance when working with high currents. Proper insulation and safety protocols are essential. Even minor mistakes can lead to severe consequences. There’s often pressure to reduce costs. However, skimping on quality can have dire results. Addressing these challenges requires diligent planning and a focus on safety.

The future of high current transformer technology is bright. Innovations are emerging at an impressive pace. These advancements focus on enhancing efficiency and reliability. Improved materials and designs lead to lighter and more compact transformers. This is crucial for industries looking to optimize space.

As industries evolve, the demand for more sustainable solutions grows. High current transformers are now being designed with eco-friendly materials. Companies are investing in smart technology. These smart transformers can monitor their own performance. This enables predictive maintenance, reducing downtime significantly.

Tips: Always consider the specific application needs before selecting a transformer. Be mindful of the environmental impact of materials used. Regularly assess technology upgrades to ensure optimal performance. The quest for efficiency is not just about improvement; it's also about finding balance.

This chart illustrates the various applications and advantages of high current transformers in modern industries. The data demonstrates the distribution of applications across sectors and highlights the efficiency gained through the use of these transformers.