Leave Your Message

In today's world, maintaining stable voltage levels is crucial for both residential and industrial applications. An Auto Voltage Controller (AVC) plays a vital role in regulating voltage fluctuations. According to a recent industry report by Grand View Research, the global market for voltage controllers is expected to reach $4.75 billion by 2026, highlighting the growing importance of these devices.

Choosing the right AVC is not as straightforward as it seems. Factors like system compatibility, capacity, and installation ease come into play. A study by MarketsandMarkets shows that 30% of users experience operational issues due to improper AVC selection. This statistic underscores the importance of thorough evaluation before making a decision.

Considering specific power requirements and potential load variations is essential. It’s easy to overlook these factors. A small mistake can lead to inadequate performance or even equipment damage. When selecting an Auto Voltage Controller, attention to detail can make a significant difference in ensuring your electrical systems run smoothly and efficiently.

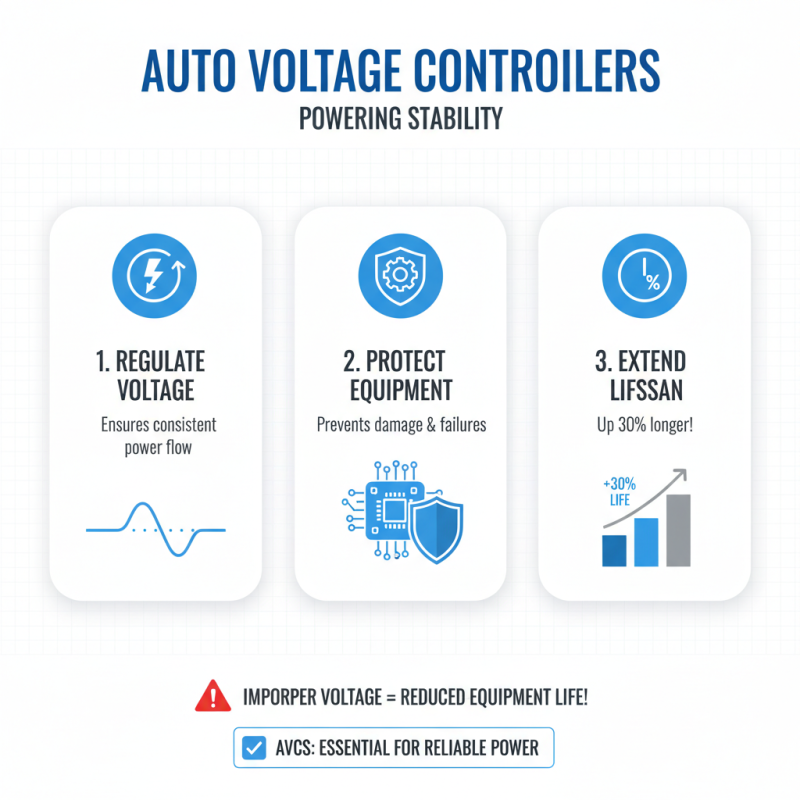

Auto voltage controllers (AVCs) are pivotal in maintaining stable power systems. They help regulate voltage levels, ensuring devices operate efficiently. In a recent industry report, it was found that improper voltage can lead to a 30% decrease in equipment lifespan. This highlights the importance of understanding how AVCs work.

Today’s power systems face challenges like voltage fluctuations. These instabilities can disrupt operations and cause damage to sensitive electronics. AVCs monitor voltage and automatically adjust it to required levels. According to another study, poorly regulated voltage can cost industries millions each year in downtime and repairs.

When selecting an AVC, consider its capacity, regulation speed, and compatibility with existing systems. Not all controllers are equal. Some may underperform or lack essential features, leading to more problems than solutions. Evaluating these factors can prevent costly mistakes. In the quest for efficiency, vigilance in choosing the right AVC is crucial.

When selecting an auto voltage controller, key specifications play a vital role. Look closely at the voltage range. Ensure it fits your equipment. An incorrect range can lead to equipment damage or inefficient performance. The capacity is another crucial aspect. It should match or exceed your system's needs.

Consider the response time of the controller. A slower response may lead to fluctuations that harm sensitive devices. Temperature tolerance levels matter too. If the controller overheats, it shortens its lifespan. Check for built-in safety features like surge protection. Such features can save you from potential hazards.

Don’t overlook installation ease. Complex setups may require professional help, adding cost. User reviews can provide insight into real-world performance issues. Look for feedback on reliability and long-term usability. Each detail contributes to the controller's effectiveness and longevity.

| Specification | Description | Importance |

|---|---|---|

| Input Voltage Range | The range of voltages the controller can accept. | Essential for compatibility with local electrical supply. |

| Output Voltage Regulation | The ability to maintain a constant output voltage. | Crucial for protecting sensitive electronic devices. |

| Maximum Load Capacity | The maximum electrical load the controller can handle. | Important for ensuring safety and functionality. |

| Response Time | How quickly the controller reacts to voltage changes. | Critical for maintaining stable output under fluctuating conditions. |

| Protection Features | Built-in features to prevent overload, short circuit, etc. | Key for ensuring longevity and safety of devices. |

| Temperature Range | The temperature variations the controller can operate in. | Vital for use in different environments. |

| Efficiency Rating | The effectiveness of the controller in converting voltage. | Important for energy savings and cost reduction. |

| Size and Weight | Physical dimensions and weight of the controller. | Relevant for installation space considerations. |

| User Interface | How easy it is to operate and configure the controller. | Influences usability and user satisfaction. |

| Warranty and Support | The warranty period and customer support options available. | Critical for resolving issues and ensuring long-term use. |

When selecting an auto voltage controller, analyzing load needs is crucial. A controller must fit your electrical requirements. Poor matching can lead to efficiency loss. For instance, a report from the International Energy Agency suggests that improperly matched voltage controllers can increase energy consumption by up to 25%. This is a significant waste in any setup.

Evaluate the total load your system will encounter. Consider both starting and running wattages. Start-up loads can be several times higher than running loads. If you underestimate, you'll face performance issues. Several experts recommend calculating your maximum load and adding a safety margin of at least 20%. This approach ensures your controller handles unexpected spikes without risking damage.

Tip: When comparing controllers, look for features that cater to your specific load profile. User reviews offer insights, but focus on technical specifications. Not all features are necessary, and some can complicate usage. Another tip: consider the ambient conditions where the controller will operate. Temperature fluctuations can impact performance. Controllers that aren’t designed for harsh environments may fail prematurely. Remember, each choice impacts longevity and efficiency.

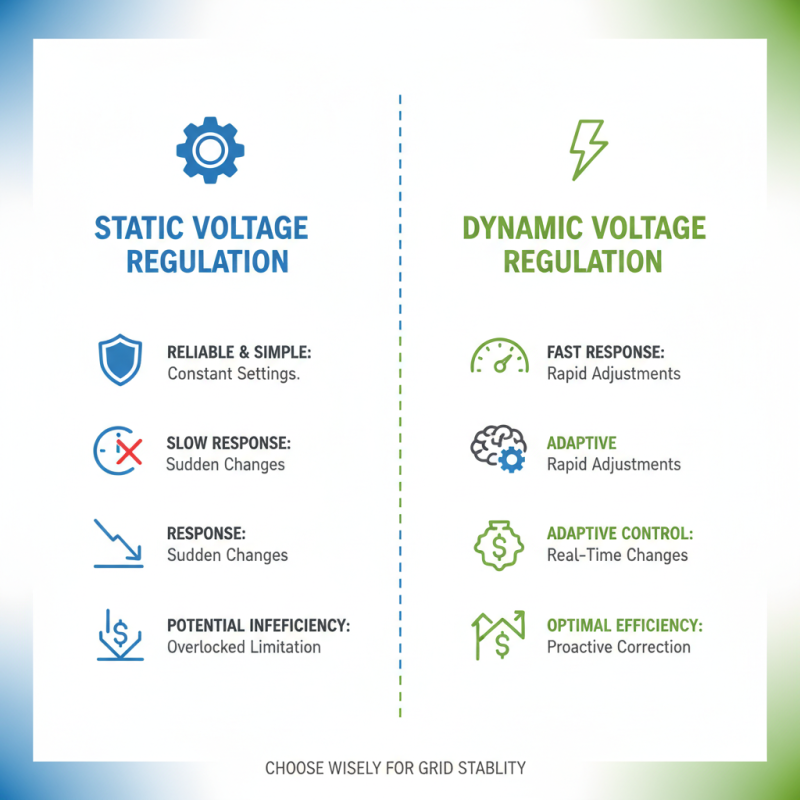

When evaluating control methods for voltage regulation, two primary types stand out: static and dynamic. Static controllers adjust voltage based on constant settings. They offer reliability and simplicity. However, they might not respond quickly to sudden changes in voltage. Users often overlook this limitation. Choosing a static method might lead to persistent inefficiencies.

Dynamic controllers, on the other hand, adjust in real-time. They adapt to fluctuating loads and provide smoother voltage control. This can be a game changer for varying power demands. Yet, they are often more complex and possibly harder to maintain. Users might find themselves overwhelmed by the setup. Weighing these factors is crucial.

Tip: Consider your specific needs. If stability is key, a static controller may be suitable. But for dynamic environments, investing in a dynamic controller could pay off. Monitor performance post-installation. Adjustments may be necessary to achieve the desired efficiency. Another tip: always consult with a professional before making your final choice. This can help prevent costly mistakes.

Environmental factors play a crucial role in the performance of auto voltage controllers. Temperature fluctuations, humidity levels, and dust exposure can greatly affect their efficiency. For instance, a study shows that controllers operating in high-humidity environments can lose up to 20% of their efficiency. Understanding these impacts is essential when selecting a controller for your needs.

Tip: Always consider the operating environment of the controller. If it will be exposed to high humidity or dust, look for a model with protective features. This could enhance longevity and performance.

Another vital factor is temperature. Extreme heat can lead to overheating, potentially damaging the controller. Research indicates that a temperature increase of 10°C can reduce the lifespan of electronic components by 50%. This emphasizes the need for robust cooling solutions in hot environments.

Tip: Evaluate thermal management options. Passive cooling systems may be sufficient in some cases, while active solutions might be necessary in more demanding settings.

Choosing the right auto voltage controller is not just about specifications; environmental adaptability is key. Ensuring the controller can withstand its surroundings can save time and costs in the long run.