Leave Your Message

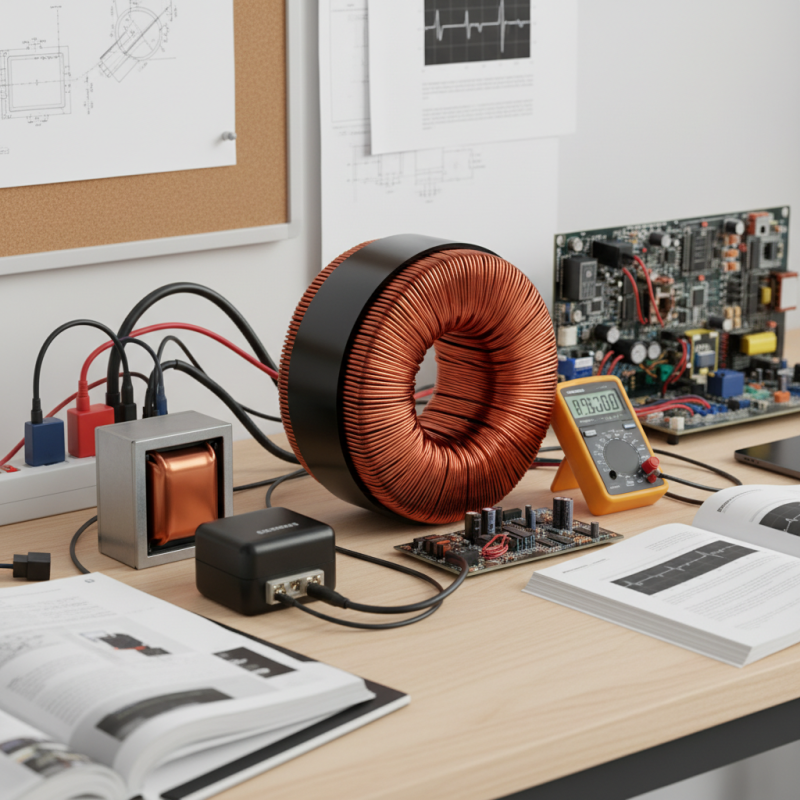

Choosing the right Power Supply Isolation Transformer is crucial for various applications. These transformers help isolate electrical circuits, improving safety and performance. They protect sensitive equipment from noise and voltage fluctuations. Without proper selection, users may face challenges like inadequate power delivery or equipment damage.

Consider your specific needs when selecting a transformer. Power requirements, size, and application type are vital factors. Each choice comes with its benefits and drawbacks. Sometimes, the best option isn’t the most powerful or expensive one. You may need a balance between cost and efficiency.

Understanding your equipment is essential. If the transformer doesn’t meet your specifications, issues will arise. Many users overlook details, assuming all transformers are created equal. Reflecting on past experiences might help avoid common pitfalls. The journey to find the ideal Power Supply Isolation Transformer requires careful thought and consideration.

Power supply isolation transformers are essential for ensuring safety and reliability in electrical systems. These devices separate the electrical circuit from the power source, reducing the risk of electric shock and protecting sensitive equipment. According to the International Electrotechnical Commission (IEC), properly chosen isolation transformers can limit fault currents by up to 80%. This indicates a significant reduction in the potential damage caused by electrical faults.

When selecting a power supply isolation transformer, consider the load requirements. The transformer's capacity must match or exceed the total wattage of connected devices. Miscalculating this can lead to overheating and premature failure. A report from the IEEE demonstrates that improper sizing is a contributing factor in 25% of transformer failures. Additionally, the type of winding configuration plays a critical role. A delta-wye configuration can help manage harmonics effectively, which can otherwise compromise performance.

It's also vital to account for environmental factors. Operating conditions like temperature and humidity affect performance. The National Electrical Manufacturers Association (NEMA) notes that moisture can decrease transformer efficiency by as much as 15%. Regular maintenance is necessary to ensure longevity and optimal performance. Ignoring these aspects can lead to costly downtime or even safety hazards.

| Feature | Description | Importance |

|---|---|---|

| Voltage Rating | The maximum voltage the transformer can handle. | Critical for system compatibility and safety. |

| Power Capacity | The amount of power (in VA) that the transformer can supply. | Must meet or exceed the total load requirements. |

| Isolation Ratio | The level of electrical isolation between input and output. | Essential for protecting sensitive equipment. |

| Cooling Method | Type of cooling, such as natural or forced air. | Affects the efficiency and longevity of the transformer. |

| Size and Weight | Physical dimensions and weight of the transformer. | Important for installation space and transport. |

| Regulatory Compliance | Standards the transformer must meet (e.g., safety, emissions). | Ensures safe and reliable operation. |

When selecting a power supply isolation transformer, key factors must be evaluated. Load requirements are paramount. Understand the total wattage your devices will consume. A transformer should handle 20% more than the maximum load. This additional capacity prevents overheating and ensures longevity. Research indicates that under-rated transformers often fail prematurely.

Voltage rating is also critical. Ensure the transformer matches your circuit voltage. Mismatches can lead to inefficiencies or damage. Additionally, consider the frequency. Many transformers operate at 50/60 Hz. Operating outside this range can affect performance. A mismatch might decrease isolation and increase noise.

Finally, think about physical space and cooling. Isolation transformers generate heat. Adequate airflow is essential. Too small a space can lead to higher failure rates. Reports suggest that over 30% of transformers fail due to insufficient cooling or overcrowding. Always plan for airflow and maintenance access. This thoughtful approach can enhance your transformer’s performance and reliability.

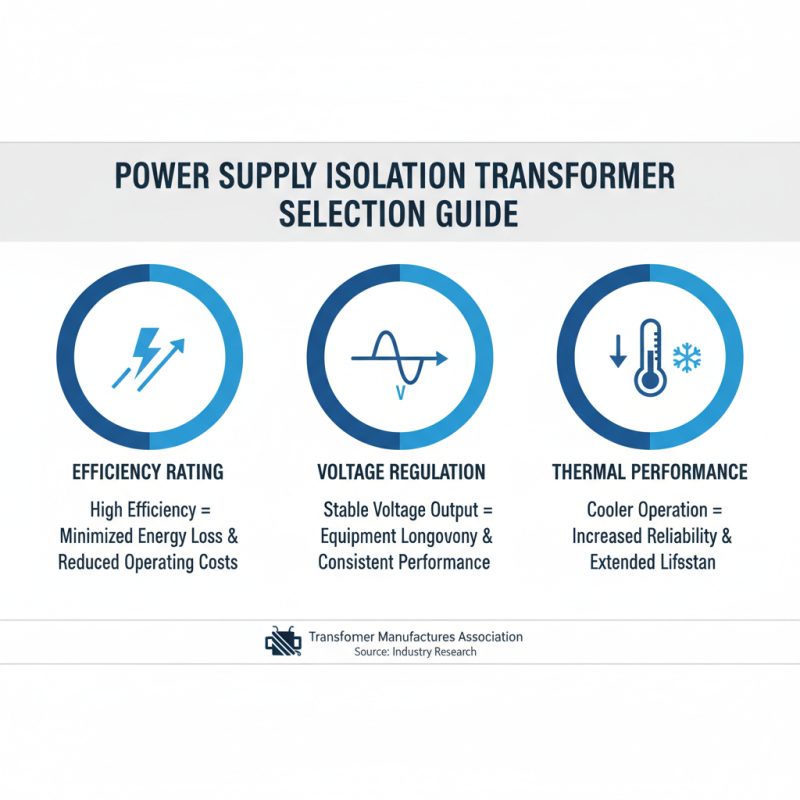

When selecting a power supply isolation transformer, performance ratings are crucial. These ratings provide a clear guide to understanding the transformer's efficiency, voltage regulation, and thermal performance. Research from the Transformer Manufacturers Association indicates that units with a high efficiency rating can minimize energy losses. This translates to reduced operating costs, especially in high-load applications.

Voltage regulation is another essential aspect. A transformer with excellent regulation maintains output voltage despite varying load conditions. According to industry standards, a rated regulation of less than 5% is ideal. However, many standard models fall short here. This inconsistency can lead to operational issues, particularly in delicate electronic installations.

It's also important to assess thermal performance. High-quality transformers typically have lower temperature rises under load. Data suggest that a temperature rise over 40°C can shorten the lifespan of the transformer. This factor is often overlooked during selection processes. Choosing a product that meets thermal specifications is vital for reliability. Each selection should be carefully considered based on your specific needs.

Choosing the right power supply isolation transformer depends largely on your specific application needs. Different equipment has unique requirements. For instance, medical devices must comply with stringent electrical standards, ensuring patient safety and equipment reliability. According to research by the International Electrotechnical Commission, 43% of medical equipment failures are linked to electrical failures. Selecting a transformer designed for these critical environments is essential.

Industrial machines require robust transformers to handle high loads. Equipment that operates in harsh environments, such as manufacturing plants, often demands a transformer that can withstand extreme conditions. Interestingly, a report from the National Institute of Standards and Technology states that about 30% of industrial accidents stem from electrical issues, underscoring the importance of matching transformers to specific industrial needs.

In contrast, standard office equipment may not require as heavy-duty a transformer. However, even office environments can benefit from isolation transformers to minimize electrical noise. A survey conducted by Electrical Engineering Magazine noted that noise-related disruptions cost businesses an average of $1,400 annually. Finding a balance between performance and cost is crucial but often overlooked. It’s easy to underestimate the impact of a well-matched transformer on operational efficiency.

This chart illustrates the application-specific needs of different types of power supply isolation transformers. The data reflects the ratings and effectiveness for various equipment types, which can help you make an informed choice.

When selecting a power supply isolation transformer, safety compliance is crucial. Industry standards govern the design and operation of these devices. Look for certifications like UL or IEC. These labels indicate adherence to safety criteria. They assure you that the transformer can perform reliably.

Your choice should consider the environment where the transformer will be used. Is it a commercial or industrial setting? Each has unique requirements. Tension could arise from differing load demands. Insufficient insulation can lead to failures. This could cause equipment damage or safety hazards.

Evaluate thermal management as well. Some transformers generate significant heat. Ensure proper ventilation or cooling systems are in place. Think about installation requirements, too. Space constraints may complicate the setup. Lastly, be mindful of future scalability. A transformer that meets current needs may not suit future demands. Planning ahead could save costs down the road.