Leave Your Message

Choosing the right High Tension Current Transformer (HTCT) is crucial for electrical systems. These devices play a vital role in measuring and monitoring electrical currents. According to recent industry reports, HTCTs account for over 30% of total transformer costs in high-voltage applications. This underscores their importance in ensuring operational efficiency and safety.

In the ever-evolving energy landscape, reliability is key. Faulty transformers can lead to significant outages. Data shows that nearly 25% of inspections reveal issues that could be traced back to inappropriate selections. Users often underestimate the impact of ambient conditions on performance. Temperature, humidity, and pollution levels can greatly influence the effectiveness of an HTCT.

Finding the right match requires careful consideration. Various parameters must be analyzed, including voltage ratings and installation environment. Many businesses face challenges in aligning their needs with available options. It is not uncommon to overlook critical specifications or features. Such missteps can result in higher maintenance costs or even operational failures. Thoughtful selection of an HTCT can mitigate these risks.

High tension current transformers (HTCTs) play a crucial role in electrical systems. They are essential for measuring high voltage currents safely. Understanding their design and function is important for effective use.

HTCTs convert high voltage currents into manageable levels. This allows sensitive measuring devices to function correctly. When selecting an HTCT, consider core material. Different materials affect performance and accuracy. Copper and aluminum are common choices. Each has its own pros and cons. The size and insulation class also matter. They impact durability and safety.

Accuracy is critical in choosing HTCTs. A small error can lead to significant issues. Make sure to check the specifications carefully. Reflect on your specific needs. Overlooked details can result in mismatches. Always seek guidance if uncertain about your choices.

When selecting a high tension current transformer, understanding key specifications is essential. Ensure you consider voltage ratings, current capacities, insulation levels, and accuracy class. According to industry reports, transformers with a higher accuracy class are crucial for precise measurements. Misestimating current can lead to substantial errors and system inefficiencies.

Tip: Check the transformer’s dimensions and weight. Proper fit in your designated space is vital. Regular stress testing may prevent potential failures that lead to costly downtime. Make sure to assess short-circuit protection as well. It’s a frequently overlooked specification, yet it plays a critical role in system safety.

Investigating the temperature rating is important too. Many transformers operate under various environmental conditions, affecting performance. A transformer with a lower thermal limit could fail prematurely, compromising system reliability. Selecting a product with appropriate thermal ratings will enhance long-term usability.

Tip: Research historical failure rates of different models and technologies. Real-world data can reveal insights some sales pitches may overlook. Aim for informed choices, rather than relying solely on specs.

Choosing the right high tension current transformer requires careful evaluation of your application needs. Different projects have unique requirements. Some might need high accuracy for metering, while others focus on protection. Understanding your specific application guides you in making an informed choice.

For instance, consider power plants and industrial setups. They often demand transformers that can handle fluctuating loads. Conversely, a simpler installation may not require such complexity. It's about matching the transformer’s capabilities with the system. Many people overlook the importance of environmental factors. High humidity or extreme temperatures can impact performance. This reflection is crucial in the selection process.

Evaluating your needs often reveals gaps in understanding. Ask yourself, how much current will flow? What level of precision do you require? These questions lead you to potential solutions. However, even with thorough preparation, unexpected challenges may arise in implementation. A mismatch between expectations and reality can occur. This aspect needs consideration during your decision-making journey.

| Parameter | Description | Value |

|---|---|---|

| Rated Voltage | The voltage level at which the transformer operates | 36 kV |

| Load Type | Indicates whether the load is resistive, inductive, or capacitive | Inductive |

| Frequency | Operating frequency of the electrical system | 50 Hz |

| Burden Rating | The maximum load the transformer can handle | 15 VA |

| Accuracy Class | Defines the accuracy of the transformer in terms of measurement | 0.5 |

| Installation Environment | Specifies the environmental conditions for safe operation | Outdoor |

| Insulation Level | Voltage rating of insulation materials used | 95 kV |

| Weight | Total weight of the transformer for handling and installation | 120 kg |

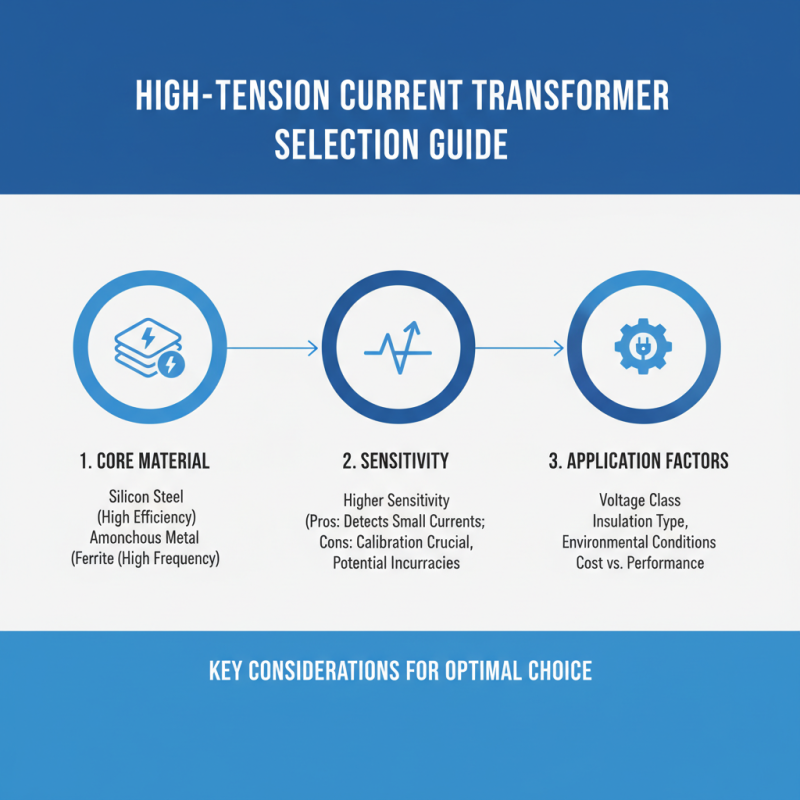

When choosing the right high tension current transformer, comparing different types is crucial. There are several key factors to consider. One significant aspect is the transformer's core material. Materials like silicon steel offer better efficiency than others. Metal or ferrite cores may also be options depending on specific applications. Some users prefer higher sensitivity. Yet, this can lead to potential inaccuracies if not calibrated correctly.

Another factor to consider is the power rating. Higher ratings allow for greater load handling, but they may be bulkier. Users must weigh the benefits of size versus capacity. Cost is always a factor too. High-quality models typically come with a steeper price tag. Still, investing in a reliable transformer can prevent costly failures down the road.

Ease of installation is often overlooked. Complicated models can lead to errors during setup. Sometimes, simpler designs work better for most applications. Many people focus strictly on specifications, ignoring practical aspects. User feedback and real-world performance can provide valuable insights. These details often highlight strengths and weaknesses that specifications alone do not capture.

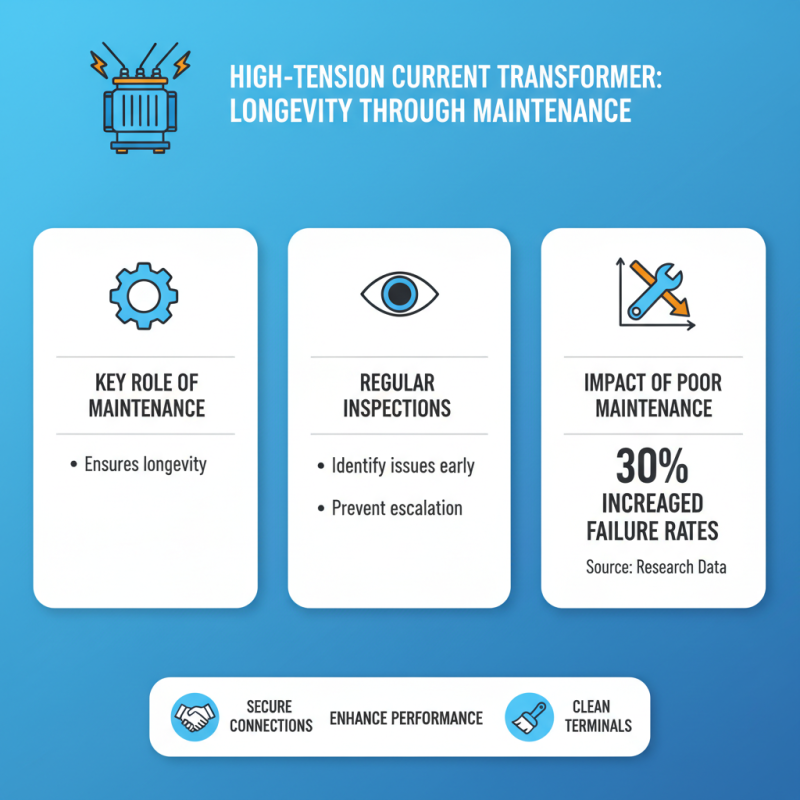

When selecting a high tension current transformer, maintenance plays a crucial role in longevity. Regular inspections can help identify issues before they escalate. Research indicates that improper maintenance can lead to a 30% increase in failure rates. Ensuring that connections are secure and terminals are clean can significantly enhance performance.

Tips: Conduct visual inspections quarterly. Look for signs of wear and overheating. Address loose connections immediately.

Transformers can degrade over time. The insulation material is particularly vulnerable. According to industry reports, 60% of failures originate from insulation breakdown. Using thermal imaging can help spot potential problems early. Keeping the environment clean and dry is vital for the operational lifespan of transformers.

Tips: Implement a routine cleaning schedule. Use dehumidifiers in a humid environment. Monitor temperature fluctuations closely.