Leave Your Message

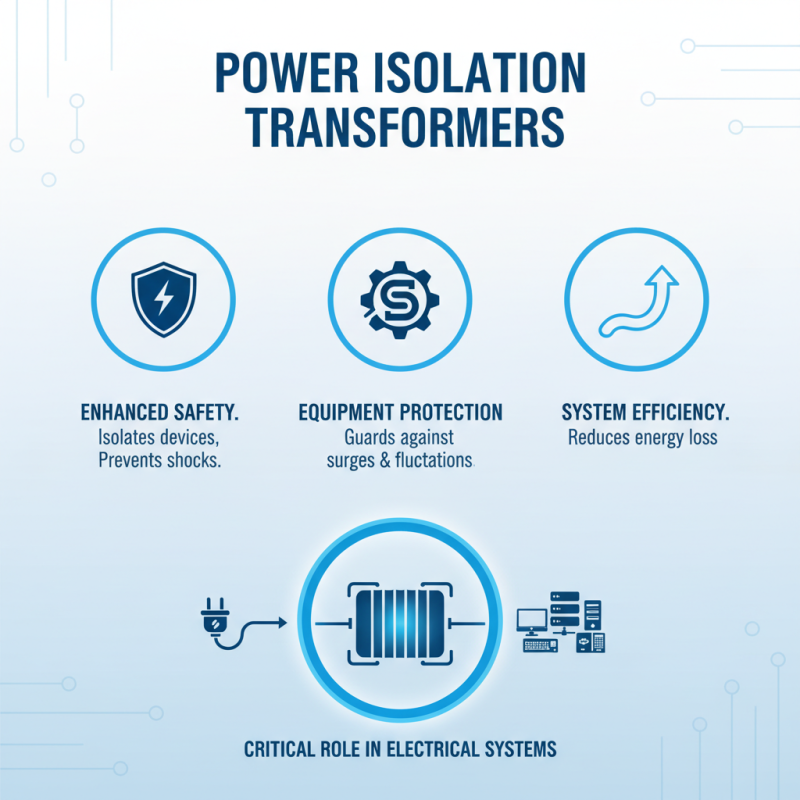

In the world of electrical engineering, the significance of a Power Isolation Transformer cannot be overstated. Experts like Dr. Emily Carter emphasize its crucial role in ensuring safety and efficiency. She once said, "Using a power isolation transformer enhances both equipment protection and user safety." This highlights the critical nature of these devices in various applications.

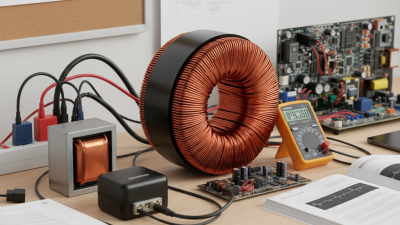

Power Isolation Transformers protect sensitive equipment from power surges and provide electrical safety. They effectively isolate the load from the power source. This minimizes the risk of electrical shock and system failures. However, the market offers a range of options, leading to confusion among consumers. It is essential to consider specific needs and circumstances when selecting one.

While many manufacturers boast advanced features, not all transformers are created equal. Selecting the wrong model can lead to inefficiencies or compromise safety. Users must carefully evaluate their choices and seek expert advice when necessary. This reflection on choices can lead to better outcomes in electrical safety and efficiency.

Power isolation transformers play a critical role in various electrical systems. They ensure safety by isolating electrical devices from the power source. This isolation protects sensitive equipment from surges or fluctuations. It also minimizes the risk of electric shocks. These transformers help maintain efficiency by reducing energy losses during transmission.

In many industrial settings, the importance of these transformers cannot be overstated. Equipment protection is paramount. However, not all setups use them effectively. Some facilities overlook their need for proper sizing and configuration. This can result in inadequate performance. It may lead to unexpected downtime or failures. Proper installation and maintenance are crucial for optimal results.

Technology is evolving, yet some outdated practices persist. Many users still rely on conventional transformers that may not meet current standards. This reflects a need for ongoing evaluation. Continuous education on power isolation solutions is essential. Emphasizing the right choices ensures safety and efficiency are achieved.

When selecting a power isolation transformer, safety and efficiency are paramount. First, consider the voltage ratings. Ensure the transformer matches your specific requirements. An improper voltage can lead to equipment damage. Choosing the right power rating is equally important. Oversized transformers waste energy, while undersized ones can overheat.

Tip: Always assess your load requirements before purchasing. A detailed analysis helps avoid common pitfalls.

Next, look at the regulatory certifications. A transformer should meet safety standards relevant to your region. Compliance ensures reliability and minimizes risks. Additionally, check for features like thermal protection and overload protection. These can help safeguard your equipment and enhance longevity.

Tip: Keep an eye on user reviews. Feedback on performance can provide insights you may overlook. This can guide your decision-making process.

Finally, consider the physical size and mounting options. Larger transformers may require more space, which can be an issue. Furthermore, installation complexity can vary greatly. Ensuring compatibility with existing setups can save time and costs in the long run. A well-chosen transformer is vital for both safety and operational efficiency.

This chart presents the efficiency ratings of various power isolation transformers. The data indicates that Transformer A has the highest efficiency, reaching 95%, while Transformer E exhibits the lowest efficiency at 89%. Choosing a transformer with higher efficiency can contribute to optimal safety and energy savings.

When considering power isolation transformers for 2026, it's crucial to identify the top brands and models. A recent industry report suggests that the demand for high-efficiency transformers is on the rise, driven by increased safety regulations. Many facilities seek trustworthy options that enhance safety and minimize energy losses. A well-designed power isolation transformer can significantly reduce electrical noise, benefiting sensitive equipment.

Leading models in this category feature robust insulation and advanced thermal management. These transformers often come equipped with integrated monitoring systems. Such features ensure real-time performance tracking, addressing potential issues promptly. However, some users report difficulties in finding replacements for specific components. Critically, it highlights the importance of considering long-term service options when selecting models.

Efficiency ratings are also an important factor. Studies indicate that transformers with higher efficiency can lead to significant savings in energy costs—up to 30% in some cases. Yet, many users underestimate the initial investment needed for high-quality options. Prioritizing both safety and performance often results in better operational outcomes. Balancing cost with quality remains a challenge for many organizations.

When selecting a power isolation transformer, safety standards and certifications are crucial. These standards ensure that the transformer can handle electrical loads safely and efficiently. Look for products that meet local and international safety regulations. Certifications like UL, CE, and ISO can assure you of the transformer's reliability.

Tips: Always verify certification labels. They provide insights into safety testing and performance.

Different applications may require different safety features. For example, transformers used in medical facilities must meet strict hygiene and safety standards. Any shortfall in compliance can pose serious risks. It’s essential to know these requirements upfront.

Tips: Ask manufacturers about their testing processes. This can reveal much about the product’s safety level.

Not all transformers are created equal. Some may lack necessary features or certifications. It’s important to be critical when evaluating options. Consider the environment where the transformer will be used. Will it be in a high-risk area? The right certifications can make all the difference.

| Model | Power Rating (kVA) | Efficiency (%) | Safety Certifications | Noise Level (dB) |

|---|---|---|---|---|

| Model A | 10 | 98 | UL, CE | 45 |

| Model B | 15 | 97 | ISO 9001, RoHS | 50 |

| Model C | 20 | 95 | CSA, FCC | 60 |

| Model D | 25 | 99 | NEBS, NEMA | 48 |

Isolation transformers are crucial for ensuring safety and efficiency in electrical systems. Regular maintenance helps to prolong their lifespan and maintain optimal performance. Checking the connections frequently is essential. Loose or corroded connections can lead to energy loss and potential hazards.

Cooling is another vital factor. Isolation transformers can generate heat during operation. Ensuring proper ventilation will minimize overheating and improve efficiency. It's also worth monitoring the ambient temperature surrounding the transformer. High temperatures can accelerate wear and tear.

Regular inspections are necessary to identify wear on insulation and components. Signs of deterioration should not be ignored. Over time, insulation can break down, leading to failures. Cleaning dust and debris also helps. A clean transformer operates more efficiently. Neglecting these details can lead to costly repairs and reduced safety.