Leave Your Message

High Voltage Current Transformers (HVCTs) play a critical role in power systems. They ensure safety and reliability in high voltage applications. Experts in the field emphasize their importance. Dr. Alice Thompson, a leading authority on electrical engineering, once stated, "Choosing the right High Voltage Current Transformer is vital for operational efficiency."

Selecting the best HVCT can be challenging. There are various types, specifications, and manufacturers to consider. Technical features, such as insulation and physical size, can greatly impact performance. Many users often overlook these aspects. A poorly chosen transformer can lead to inefficiencies. The repercussions can be costly in both time and resources.

Investing in high-quality HVCTs is essential. Yet, some organizations still opt for lower-cost options, potentially compromising safety. Awareness and education about these transformers are necessary. Understanding their applications can help in making informed decisions. Ultimately, the right choice fosters a dependable power system, benefiting everyone involved.

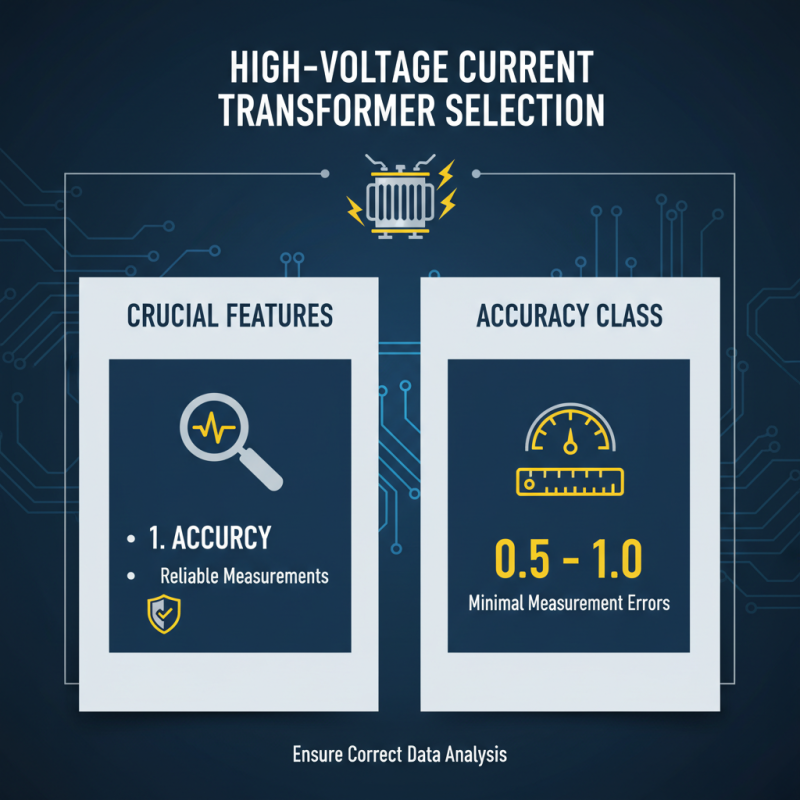

When selecting a high voltage current transformer, several features are crucial to consider. Accuracy is a top priority. A current transformer must provide reliable measurements to ensure correct data analysis. According to industry reports, high-quality transformers typically have an accuracy class of 0.5 to 1.0. This range ensures minimal measurement errors in high voltage applications.

Another important aspect is insulation strength. High voltage transformers should withstand extreme conditions. They often have an insulation rating of at least 15 kV. This rating protects against electrical faults and enhances system safety. Environmental factors also matter. Consider temperature ranges and humidity levels in the installation area. These factors can impact the performaance and longevity of the transformer.

Tips: Check the standards and certifications of the transformer. Ensure it meets international safety regulations. Regular maintenance is vital; neglecting it might lead to performance issues over time. Investing in a high-quality current transformer can save costs in the long run, especially when considering repair or replacement needs. When it comes to size, evaluate the physical dimensions, as space constraints can determine your options. Choosing wisely makes a significant difference in operational efficiency.

In 2026, the market offers various types of high voltage current transformers. These devices are critical for monitoring electrical systems efficiently. They come in different designs, each serving specific needs. One common type is the traditional wound current transformer. This design features coils wrapped around a core. It provides accurate measurements but may face issues with size and weight. These transformers can be bulky, limiting their use in tight spaces.

Another option is the hall effect current transformer. This type uses magnetic fields for measurement. Its compact size and lightweight design make it advantageous for modern applications. However, hall effect transformers may require calibration, which can be a hassle. Then there’s the split-core transformer, which offers flexibility. Users can easily install it without needing to disconnect wires. This convenience comes with trade-offs regarding accuracy.

In addition, emerging technologies like digital transformers are making waves. They promise enhanced data processing capabilities for real-time monitoring. Yet, these advanced units could be complex to operate. Users might struggle with new software or interfaces. The evolution in high voltage current transformers reveals many choices tailored to diverse applications. Each type has strengths and potential drawbacks that users should consider carefully.

This bar chart illustrates the different types of high voltage current transformers available in 2026, along with their corresponding voltage ratings and operational capabilities.

Choosing the right high voltage current transformer can be a daunting task. The market offers various options, making it crucial to identify reliable brands and models. According to the latest industry report, the demand for high voltage current transformers has increased by 15% annually. This growth highlights the importance of quality and performance.

Many models stand out due to their accuracy and durability. For instance, a reputable transformer typically has a linearity of better than 0.5%. This ensures precise measurements and enhances overall system reliability. Poor-performing models can lead to significant losses and operational inefficiencies. The risk of inaccurate readings can compromise the safety of installations.

Materials used in manufacturing these transformers are vital. High-grade insulation materials improve lifespan and reduce maintenance needs. Conversely, cheaper materials may result in frequent failures. Companies should be cautious and invest in better quality options. Ignoring this aspect can lead to unwanted downtime and repair costs. Investing in a high-quality transformer might seem expensive initially, but it often proves cost-effective in the long run.

| Model | Voltage Rating (kV) | Current Rating (A) | Accuracy Class | Weight (kg) | Price ($) |

|---|---|---|---|---|---|

| Model A | 72.5 | 2000 | 0.2 | 50 | 450 |

| Model B | 145 | 3000 | 0.5 | 60 | 750 |

| Model C | 245 | 4000 | 0.1 | 75 | 1200 |

| Model D | 420 | 5000 | 0.15 | 88 | 1700 |

| Model E | 550 | 6000 | 0.2 | 90 | 2200 |

High voltage current transformers (HVCT) play a critical role in various industries. They are essential for accurate measurement and monitoring within electrical power systems. Utilities rely on these devices for power generation, transmission, and distribution. They help ensure safety and efficiency in operations.

Applications extend to renewable energy, such as wind and solar power. HVCTs are crucial in connecting these sources to the grid. However, the integration of HVCTs can present challenges. Their installation requires careful planning. Miscalculations can lead to inefficiencies and increased costs.

There are also some limitations to consider. Regular maintenance is necessary to prevent system failures. In some cases, the physical footprint of these transformers can be an issue. Companies may need to optimize space without sacrificing performance. The right HVCT choice can greatly vary based on specific needs and conditions. Each situation demands a tailored approach for the best results.

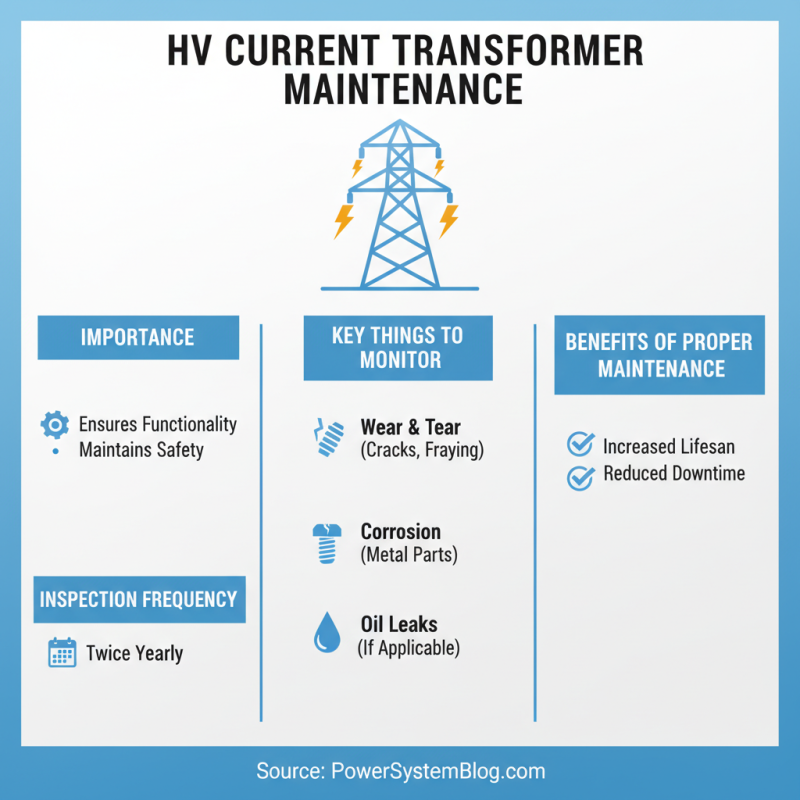

High voltage current transformers (HVCTs) play a vital role in power systems. Proper maintenance ensures their functionality and safety. Understanding what to monitor can make a big difference. Regular inspections should occur at least twice a year. Look for signs of wear and tear. Corrosion can be a hidden culprit.

Tips: Ensure all connections are tight. A loose connection can cause overheating. An infrared camera can help spot issues without direct contact. Also, check the insulation regularly. Insulation breakdown leads to failures. You must replace it before it fails completely.

Safety is crucial in dealing with HVCTs. Always wear appropriate protective gear. This includes gloves and helmets. Ensure that only trained personnel handle these devices. They must understand safety protocols. Working near high voltage lines is inherently dangerous. Take these risks seriously. Proper training is not optional. It is essential for safe operation.